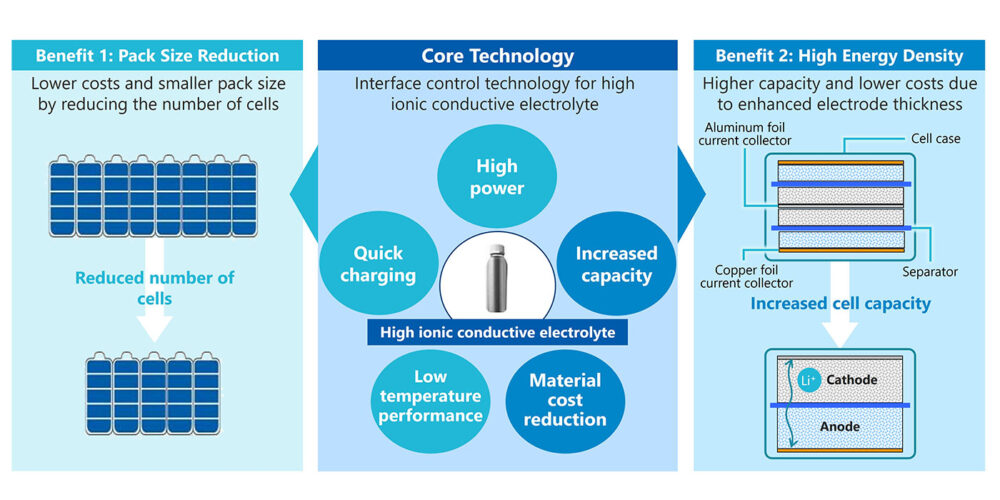

The Japanese technology company Asahi Kasei announced it successfully achieved proof of concept (POC) of lithium-ion batteries (LIBs) using its proprietary high ionic conductive electrolyte. “This technological breakthrough allows for increased power output even at low-temperature, and improved durability at high temperature – both pressing issues of current LIBs. Furthermore, this technology can contribute to lower cost and smaller size of battery packs, further raising the energy density,” Asahi Kasei said.

LIBs are recommended to be used within a temperature range of 10 to 45°C. Lower temperatures result in lower cell capacity, lower power output, and longer charging times, while higher temperatures result in accelerated aging which reduces battery service life. With the rapidly emerging market of energy storage systems worldwide, especially in the field of electric vehicles, stable battery performance and high durability at extreme temperatures is of significant importance, the company said.

Enabling battery size and cost reduction

Asahi Kasei began developing an electrolyte with high ionic conductivity in 2010, when Honorary Fellow Akira Yoshino focused on acetonitrile as a promising ingredient in lithium-ion battery electrolytes, the company said. By using the high ionic conductive electrolyte, it is possible to reduce batteries pack size while maintaining the power output, contributing to higher battery energy density and lower overall pack cost. The projected benefits are shown in graphic.

Commercialization planned for 2025

Compared to cells made with conventional electrolyte, the tested prototype cylindrical cells showed high power at −40°C and double the cycle life at 60°C before reaching a state of health (SOH) of 80%. Commercialization is targeted for 2025, according to Asahi Kasei.